Show Related Categories

- Fast Delivery

to:

Filter By Type

Toggle Light Switch

Decorator / Rocker

Duplex Outlet

Blank

Single Outlet

Coax

Phone Jack

Filter By Color

Filter By Number of Gangs

1-Gang

2-Gang

3-Gang

4+ Gangs

Filter By Theme

Filter By Availability

Filter By Features

Filter By Size

Filter By Customer Rating

Filter By Price

Minimum

Maximum

Filter By Brand

Search: Brand

Filter By Subject

Yellow Switch Plates

429 Items

Recommended

Sort By

6 Colors

No Subject 1 - Gang Duplex Outlet Standard Wall Plate

By WorldAcc

Yellow

Rated 3.5 out of 5 stars.2 total votes

$16.99

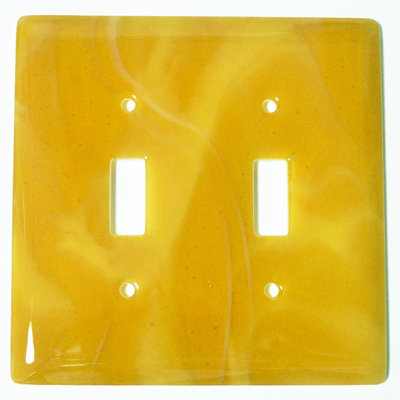

Bharat No Subject 2 - Gang Toggle Light Switch Wall Plate

By Ebern Designs

$49.30 was$58.00

FREE Delivery